class 100 clean room definition

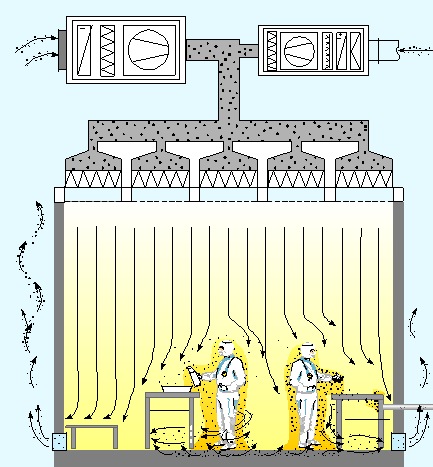

Up to 4 cash back How to clean a Class 100 ISO Class 5 Cleanroom. An ISO 5 Class clean room also known as Class 100 cleanroom is a soft- or hard-sided wall manufactured structure that utilizes HEPA filtration systems to maintain air cleanliness levels.

Pharmaceutical Clean Room Class 100 With Hepa Filtration China Parmaceutical And Filter

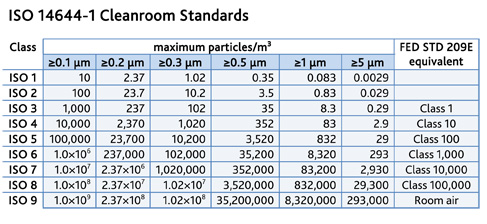

Cleanrooms are classified according to the number and size of particles permitted per volume of air.

. What is class 100 000 cleanroom - iso class 8 clean room. Air cleanliness in our cleanroom We built our cleanroom in 1996 inside. Class 100 Cleanroom is the third classification type of the FED-STD-209 classification standard the Class 100 Cleanroom corresponds to the Class 5 Cleanroom of the ISO standard.

As the highlighted portions of the chart indicate our cleanroom is Class 100- and Class 1000-rated ISO 5 and ISO 6. Once fully built and operational an isolated cleanroom is free. A cleanroom is an enclosed area of a facility designed to maintain extremely low levels of contaminants such as vaporized particles airborne organisms and dust.

Class 100 000 cleanroom has a maximum particle count of 100 000 particles per cubic foot in air. A cleanroom classification measures the level of cleanliness by calculating the size and quantity of particles per cubic volume of air. Gowning room airlock.

ISO 8 cleanrooms also known as Class 100000 cleanrooms can be modular or soft-walled and have a maximum particle count of 100000 particles 05 um per cubic foot. Custom Class 100 cleanroom benches. In addition to particle control the cleanroom is temperature and.

Grade A this defines the local zone for high-risk operations like filling zone stopper bowls open ampoules and vials and making aseptic connections. The units begin at ISO 1 and go to ISO 9 with ISO 1 being. A typical cleanroom is designed to keep outside contaminants and particles at a minimum based on the ISO clean room standards.

Large numbers like class 100 or class 1000 refer to FED_STD-209E and denote the. Sterile compounding is classified into 3 risk groups. CSPs utilizing a laminar flow workstation within a clean room.

A class 100 cleanroom maintains less than one hundred particles larger than 05 microns in each cubic foot of air space. Room with a defined concentration of airborne particles designed and used in a way that the number of particles introduced into the room or originating and being deposited in the room is. If you really value your data Gillwares class 100 clean room is the best option in the industry.

If this seems like an appealing option you should reconsider.

Class 100 Clean Room Acs Data Recovery

Understanding Cleanliness Classifications For Life Science Facilities Pharmaceutical Engineering

An Overview Of Iso 14644 Clean Room Classification Pharmaguideline

Clean Room Classifications Iso Standards Quotes 48 Hours

What Are The Different Types Of Clean Room Classes And Standards

Groundwork For Next Gen Microchips

What Is Iso 8 Cleanroom Classification

Cleanroom Classification Standards Designtek Consulting Group Llc

Cleanroom Classification Classes And Standards Portafab

Inside Our Class 100 Class 1000 Cleanroom High Purity Systems Inc

Portafab What Is A Clean Room Cleanroom Design Classification

Cleanroom Classification Classes And Standards Portafab

Portafab What Is A Clean Room Cleanroom Design Classification

Factors In Choosing The Iso Class Of A Cleanroom Monmouth Scientific

![]()

Factors In Choosing The Iso Class Of A Cleanroom Monmouth Scientific

Cleanroom Center For Nanoscale Science And Engineering

Inside Our Class 100 Class 1000 Cleanroom High Purity Systems Inc